Prefab: Global Affordable Housing Solutions

Speaker:

James B. Guthrie, AIA

Miletus Group, Inc.

The global need for affordable housing is massive and growing rapidly. India alone estimates that they currently have a housing shortage of over 18 million dwelling units, and that number continues to grow. China and many African nations are in a similar condition with population growth fast out pacing housing production. Skilled construction labor is in short supply.

Working with an international consortium, James B. Guthrie, AIA, president of Miletus Group, Inc., has developed designs and a design-build strategy to bring the benefits of prefabrication and modern methods of construction to worldwide areas of need.

James will share the story of the design, its design-build process, and how this international team came together to offer a new scheme for building worldwide affordable housing.

Brown Bag Roundtable: Modular Architecture

Tuesday, March 25, 2014 — 12:00 – 1:30PM

AIA San Diego Chapter Office

233 A Street, Suite 200

San Diego, CA 92101

http://www.aiasandiego.org

Modern Desert Prefab

Guest Speaker: Richard Orne, Architect

AIA San Diego Modular Architecture

Brown Bag Meeting Nov 26, 2013

With a dramatic 10 acre sweeping Borrego Springs desert site, a creative approach and a kit of prefab parts, Richard Orne, Architect designed and built his own modern desert home. An example of the best of Borrego Modern design, the house uses cutting edge systems-based construction technology to build a house that is in tune with its context.

AIA members are welcome to come hear about this impressive implementation of offsite construction from the architect/client’s perspective.

Richard Orne, Architect will share his thoughts and experiences on building with a set of systems based building tools to achieve a custom work of Architecture.

AIA members are welcome to join the meeting. Lunch will be provided by the AIA.

Brown Bag Roundtable: Modular Architecture

Tuesday, November 26, 2013 — 12:00 – 1:30PM

AIA San Diego Chapter Office

233 A Street, Suite 200

San Diego, CA 92101

http://www.aiasandiego.org

ACSA Offsite Conference in Philadelphia

Offsite Conference was Historic

The Association of Collegiate Schools of Architecture (ACSA) recently (September 27-29, 2012) concluded their fall conference Offsite: Theory and Practice of Architectural Production in Philadelphia. Miletus Group was proud to sponsor the keynote address: Offsite in the UK. It was given by Jaimie Johnston, Director at Bryden-Wood, London. Miletus President James B. Guthrie, AIA also moderated a couple of panels and attended a number of the papers given. Schools from all over the US and several other countries were represented as both presenters and attendees.

Bryden-Wood

BAA Airport Corridor Product

The depth of the research and conversation was impressive. This may be the first time so much brain power has been singularly focused on the discussion of the past, present and future of offsite and prefabricated construction methods in architecture. It gives one hope that the architectural community is embracing this method of construction with a greater depth of interest and knowledge than it ever has before. In the past we have seen some dabbling by some famous and not so famous architects, but at the ACSA conference there was a very real depth and breadth to the conversation of offsite as an architectural solution. It remains to be seen if this event will be The inflection point of offsite moving from an architectural novelty to an integrated part of the building of architecture, but it may very well be.

As Guthrie pointed out in his keynote introduction: “If we look at the long history of iron and steel in architecture, we see its roots as a non-architectural structural building material at the beginning of the 19th Century. At that time it was embraced by structural and cost engineers. 80 years later, a French bridge engineer caught the world’s imagination by building the functionless yet dramatic Eiffel Tower. About that same time Jennings and Sullivan were in Chicago developing the first architectural expressions based on iron. It took another 40 years until Mies turned it into poetry. In the historic arc of offsite construction, we are at the time of Sullivan. The coming years should prove very exciting as architects learn to use and exploit offsite.”

The papers from the ACSA fall conference on Offsite will be published soon.

For more on ACSA: http://www.acsa-arch.org

Special PreFab Guest and Training at AIA SD Modular Architecture Brown Bag July 24-25

Special Guest: Researcher, Educator and Author Ryan Smith

Modular Hotel Netherlands

(c) James B. Guthrie, AIA

Ryan Smith, author of PreFab Architecture (Wiley 2010) and Professor of Architecture at U of Utah, will be attending the July meeting of AIA SD’s Brown Bag Round Table discussion of modular and prefabricated architecture. This meeting will be a casual and open discussion format. Come and share your questions and experiences on the current and future state of prefabrication in architecture. Topics to include the prefabrication process in design and building, lean construction, green building, integrated technologies, global developments and more. For more information: http://www.aiasandiego.org

You are also invited to attend Prof. Smith’s more formal Offsite Design Workshop on Wednesday July 25 at the AGC training facilities in San Diego. This is a half-day morning seminar that will provide more detailed information on prefabrication in architecture and building. AIA members can earn 5 continuing education LUs. For more information: http://www.prefabeducation.com/Prefab_Education/San_Diego.html

All AIA members and allied building professionals are welcome to join these meetings.

Brown Bag Roundtable: Modular Architecture

Tuesday, Tuesday July 24, 2012 — 12:00 – 1:30PM

AIA SD Offices, 233 A Street, Suite 200, San Diego, CA

Offsite Design Workshop (5 AIA LU’s)

Wednesday July 25, 2012 — 8:00 – 12:00PM

AGC Training Facility, 6212 Ferris Square, San Diego, CA

Modular Architecture Q&A: Modular Shapes

Below is the next post, number 6, in the continuing series of prefab/modular Q&A asked by Norman Gray, a graduate student at the New School of Architecture and Design in San Diego, CA and answered by James B. Guthrie, AIA, President of Miletus Group, Inc.

Question:

How can prefab modules be designed so that they are not only rectangular or limited to prefabricated looks like stacked blocks?

Answer:

That is an easy one. Owners and developers who want to build prefab or modular architecture should hire an architect. There is no question that the supply chain in the US has been stuck with boring boxy forms. However, this has more to do with a lack of creative pressure than anything else. While the analogy to Lego® blocks can be fun, there is nothing that requires prefabrication of building components to be as repetitive in form as rectilinear blocks. Blocks do have some efficiencies, but they are minimal. A creative architect who understands how prefab building is done can come up with non-rectilinear forms that can be built as easily as common box forms.

Related link: http://www.newschoolarch.edu

© Miletus Group, Inc. 2012

Zero Net Energy Classroom at Modular Architecture Group

Zero Net Energy Classroom at Modular Architecture Brown Bag Group meeting Jan 31, 2012 in San Diego

The discussion will include American Modular Systems’ CHPS verified and award winning zero net energy Gen7 modular classroom.

January’s guest will be Jim Wallace of AMS. AMS is a California manufacturer of commercial, institutional, and modular buildings.

All AIA members are welcome to join the meeting.

Brown Bag Roundtable: Modular Architecture

Tuesday, January 31, 2012 — 12:00 – 1:30PM

AIA San Diego Chapter Office

© Miletus Group, Inc. 2012

Modular Architecture Q&A: New Materials or Technologies

Below is the next post, number 5, in the continuing series of prefab/modular Q&A asked by Norman Gray, a graduate student at the New School of Architecture and Design in San Diego, CA and answered by James B. Guthrie, AIA, President of Miletus Group, Inc.

Question:

Are there any new materials or technologies which are making prefab construction more cost effective?

Answer:

As far as I am aware, no none that directly pertain to offsite construction.

There are some new building materials on the horizon that show promise, but as of yet they have not made it into prefab production. At this time, the cost benefit of prefab is in the process, not the materials. This could easily change in the near future as the supply chain becomes more robust, but for now the focus has been on tweaking standard methods to make building more cost effective.

Manufacturing processes that allow repetitive work to be done quickly is the chief driver of prefab right now. Quick assembly once on the site is another. Use of sustainable building practices is yet another. Perhaps one aspect of using manufactured processes that is a new benefit to the building world is the idea of greater precision in building. Products produced in a factory setting are inherently built more accurately than on site work. This can translate into stronger and more efficient buildings. The application of the methodology to architecture is somewhat new. The building materials and technologies, however, still tend to parallel standard construction.

Related link: http://www.newschoolarch.edu

© Miletus Group, Inc. 2012

Modular Architecture Q&A: Project Size vs Economics

Below is the next post, number 3, in the continuing series of prefab/modular Q&A asked by Norman Gray, a graduate student at the New School of Architecture and Design in San Diego, CA and answered by James B. Guthrie, AIA, President of Miletus Group, Inc.

Question:

Is there a minimum size for a project to make prefab economically viable?

Answer:

No. Prefab is a generic concept that has been used to make buildings as small as garden sheds (1 small module) and as large as a 24 story apartment building (500+ large modules). Viability is determined by all the factors that go into making the building, including understanding the supply chain that produces the factory made components and the efficiencies inherent in that chain.

In the case of the garden shed, the sheds are standard designs produced by the hundreds, if not thousands. In the case of the 24 story building, the resulting building is a single architectural structure. One commonality that lead to the economic success in both examples is the use of repetition where repetition made sense. In the case of the garden shed, repetition is probably obvious as each shed is a copy of a singular design. In the example of the 25 story building, the architect cleverly exploited repetition in the layout of the apartments so that very few unique modules were used yet an overall creative architectural solution was achieved.

The fundamental lesson of economic viability here is that if you want to use prefab for a small building, make many replicas of the same building. If you want to use prefab for a large building, make it from many similar components.

Related link: http://www.newschoolarch.edu

© Miletus Group, Inc. 2011

Modular Architecture Q&A: Transportation Costs

Below is the second post in the continuing series of prefab/modular Q&A asked by Norman Gray, a graduate student at the New School of Architecture and Design in San Diego, CA and answered by James B. Guthrie, AIA, President of Miletus Group, Inc.

Question:

Is transportation of prefab/modular units a significant cost factor?

Answer:

The general answer would be ‘yes’, but how significant is dependent on the details of the project. These details include: the distance and travel conditions between the project and the factory, the size and weight of the prefab components, and the cost of labor at the two locations. To illustrate the extremes, I am aware of projects that were as simple as lightweight bathrooms pods built less than a mile from the project site, to very heavy fully furnished apartment modules that were shipped hundreds of miles, over both seas and roads, and even between two countries. The cost of the transportation was clearly very different being much greater in the second example, yet both projects made financial sense.

To understand the impacts of transportation, keep in mind that costs associated with transportation are not new or exclusive to prefab vs site built. All building construction has transportation costs inherent in the project. Regardless of the method of construction, both materials and labor come from somewhere other than the construction site.

To understand the differences, however, let’s first consider the case of the transportation of labor. In this regard, offsite construction is particularly efficient vs onsite. Workers at a factory tend to live near the factory and so have very consistent and minimal travel distances to the work site (ie the factory). Additionally, carpooling and other energy efficient commuting options become very real in this scheme. In the case of onsite construction, the travel distance for labor is a variable and completely dependent on the location of the trades needed and the building being constructed. Onsite construction requires a more skilled labor force than offsite construction. It is often the case the specialty trades will travel greater distances to reach a construction site than unskilled labor to factories. For onsite construction the location of the worker to the work site is in constant flux with each building built. This is not so with offsite methods.

There is a similar effect with the delivery of materials. Offsite construction occurs on singular factory sites where there tends to be large and protected staging areas. This means materials can be ordered and stored in weather protected areas in bulk far in advance of assembly. Factories also tend to be geographically clustered and located within proximities to construction material suppliers. These two factors greatly increase the efficiency of material delivery to the point of assembly.

For prefab, there is then unique cost of transporting large assemblies to the building site. Unlike traditional onsite labor and material logistics, however, prefab assemblies carry with them substantial embodied bulk material and embodied bulk labor, and are thus extremely efficient transportation hauls.

Because of these efficiencies and the addition of labor to the total transportation cost of building, the equation of transportation related costs and its percentage of the total building cost, has many components and modifiers to consider in the final equation. This is why, depending on the project, it can actually be cost effective to ship large and heavy modules long distances.

Related link: http://www.newschoolarch.edu

© Miletus Group, Inc. 2011

Architectural Blogs of Note

New to our blog this week is a feature that we will return to on a regular basis called, “Architectural Blogs of Note.” If you have an architectural blog you feel is noteworthy – please feel free to share the link by adding it to the comments area below. These blogs are selected for their quality and contribution to the online architectural knowledge base. As architects and bloggers we have a responsibility to continuously evolve our profession through smart and vibrant discussions, education, and involvement. We hope you enjoy our blog selections.

ARCHITECTURE BUZZ!!

http://www.architecture-buzz.com/

ARCHITECTURE BUZZ offers select architecture works from around the globe. Tanakorn Koomrampai, CEO of Ergo Architect in Thailand is Managing Editor of the site and provides detailed photography, facts, and thoughtful overviews of architectural sites, award winning designs, and technology.

iModernHome

http://www.imodernhome.com/

iModernHome features beautiful photography of contemporary homes, furniture, toys, and more. The site is clean and easy to navigate with succinct overviews of the featured designs.

+Mood

http://www.plusmood.com/

+Mood is an online resource for all things relating to contemporary architecture and design. The site reviews a wide variety of projects and products well organized by category and industry served.

inhabitat

http://inhabitat.com/architecture/

Inhabitat.com is devoted to the future of design, tracking the innovations in technology, practices, and materials that are pushing architecture and home design towards a smarter and more sustainable future. Founded by NYC designer Jill Fehrenbacher as a forum for investigating emerging trends in product, interior, and architectural design.

BLDG BLOG

http://bldgblog.blogspot.com/

BLDG BLOG is devoted to “architectural conjecture, urban speculation, and landscape futures.” Essayist Geoff Manaugh explores design, art, and culture with an intellectual edge.

© Miletus Group, Inc. 2011

Jobsite Mobile Office’s® Green Fleet® will be a featured attraction at the BCA Construction and Design Expo – Indiana’s largest construction trade show

The Green Fleet represents the world’s first eco-friendly HPMO (High Performance Mobile Office®) developed by the Miletus Group for Jobsite Mobile Offices. Jobsite Mobile Offices will feature the new Green Fleet HPMO at the BCA Construction and Design Expo – September 28-29, 2011 – Memorial Coliseum Exposition Center – Fort Wayne, Indiana. The 1260 HPMO will be located at the show entrance and will be fully furnished, manned, and powered.

Designed by the modular architecture specialists at Miletus Group, Inc., the HPMO installation is a pinnacle part of Jobsite Mobile Office’s 40th anniversary celebration taking place at the show.

About the Green Fleet HPMO Design

“We are proud of the work we did in partnership with Jobsite,” states James B. Guthrie, AIA, Miletus Group president. “The revolutionary HPMO uses at least one third less energy than conventional mobile offices. Some customers are reporting energy savings of well over 50%. This new thinking in mobile office design also includes a high level of recycled materials and is 100% recyclable at the end of its long life cycle. Our team spent a great deal of time analyzing the best sustainability practices in the building industry and then found ways to apply them to the mobile and modular office-building sector. Little will appear changed to office occupants in terms of the general layout, construction, and convenience of the high performance units. However, noticeable differences will appear in the form of substantially lower utility bills and significantly higher levels of comfort during hot summer and frigid winter months,” says Guthrie.

The Jobsite Green Team celebrates their 40th Anniversary at the BCA Construction and Design Expo. The Miletus Group designed the innovative HPMO to be featured at the Expo.

Miletus Group’s new Chicago office featured on Inside Indiana

Inside Indiana featured Miletus Group’s expansion to the Chicago area and quoted president James Guthrie stating, “The move is a good fit because of its proximity to the company’s headquarters and history of architectural innovation.” For more on the move, please link to the article here to read on.

McGraw Hill: Prefabrication and Modularization

McGraw Hill Construction’s recent publication of “Prefabrication and Modularization: Increasing Productivity in the Construction Industry” provides a deep look into current thinking and trends surrounding off-site construction in the US. Overall, the report is very good and worth taking the time to read and ponder the implications of its contents.

While it is a bit disappointing that McGraw Hill did not tackle the important but less tangible aspects of architecture and design, the contents do provide the reader with a broad understanding of the benefits of this method of construction. Architects who read it won’t walk away with an immediate or complete tool set for how to design buildings for off-site construction, but, and this is also important, they will have a few more heavy duty tools for talking to their clients about it as an option for their upcoming architectural projects. According to the report, the number one reason that off-site is not used on more building projects is because “the architect did not design it into the project.”

Why should architects care? The report does a very good job of answering this question. According to McGraw Hill’s research, prefabrication and modularization offers the building process many improvements in a number of key fronts. These include:

- Improved Project Schedules

- Reduced Cost and Budgets

- Site Safety

- Green Building and Waste Reduction

The report goes into great detail about its findings in these areas. If you want some tools to learn about and be able to talk to the issues of increasing construction productivity, we invite you to read the report for yourself.

– – –

The Modular Building Institute Educational Foundation is offering a limited number of full color printed editions this report in exchange for a $100 or more tax-deductible donation to the Foundation. You can contact us through the comment area if you would like to make a donation and receive a copy/copies of the report.

© Miletus Group, Inc. 2011

McGraw Hill: Increasing Productivity in the Construction Industry

McGraw Hill Construction recently published a document called: “Prefabrication and Modularization: Increasing Productivity in the Construction Industry.”* This is the latest in their Smart Market Reports, a series they publish on construction industry trends.

McGraw Hill Construction recently published a document called: “Prefabrication and Modularization: Increasing Productivity in the Construction Industry.”* This is the latest in their Smart Market Reports, a series they publish on construction industry trends.

A lot of research went into the report and it contains many interesting sub-topics. However, it only takes a quick look at the cover to find the first item of note. The report’s sub-title is: “Increasing Productivity in the Construction Industry.”

Most people who work in the construction industry are keenly aware that traditional site-built methods of construction have a bad reputation when it comes to efficiency. Likewise, most building owners and developers are keenly aware that those efficiencies hit the pocket book hard as they manifest themselves as poor quality work, change orders and completion delays. That McGraw Hill chose to include off-site construction in the general discussion of how we build all buildings is a huge step in the right direction of understanding that there is a better option in the way we create and assemble buildings.

This is a significant notion. Most non-industry discussions about prefabrication tend to see it as an anomaly, a mere curiosity for small scale players. They relinquish ‘prefab’ to the sidelines of the greater discussion of how we build all buildings, big and small. Those of us who currently practice in the off-site industry understand how efficient this method of construction really is and generally have a large vision of how important a role it can play in curing the productivity woes found with on-site construction. That McGraw Hill decided to take this on with an in depth analysis is in itself worthy of mention.

* While primarily researched and published by McGraw Hill, this Smart Market report included a number of partners. One partner was the Modular Building Institute Educational Foundation, of which James B. Guthrie, AIA, President of Miletus Group, is the Chair.

– – –

The Modular Building Institute Educational Foundation is offering a limited number of full color printed editions this report in exchange for a $100 or more tax-deductible donation to the Foundation. You can contact us through the comment area if you would like to make a donation and receive a copy/copies of the report.

© Miletus Group, Inc. 2011

Miletus Group Returns to its Roots! Opens Chicago Architectural Office

Miletus Group has officially announced the opening of its new office in Chicago, IL at 2823 N. Milwaukee Avenue, Suite E, (312) 265-6447. The new Chicago metropolitan location will house architectural services, building on the continued success of the Miletus Group management, design, and production operations in its Rochester, IN headquarters.

“The new design office gives us a great new platform to reach out to the entire Chicago metropolitan market,” says James B. Guthrie, AIA, president of Miletus Group, adding, “We have exciting plans for innovative, large-scale modular solutions involving hotel, apartment, and healthcare facility projects,” he further explains. “Chicago is a natural market for substantial building in these sectors, making it a perfect fit for our future growth strategy. In addition, Chicago is my hometown, so I very much look forward to working there with our staff of talented architects.”

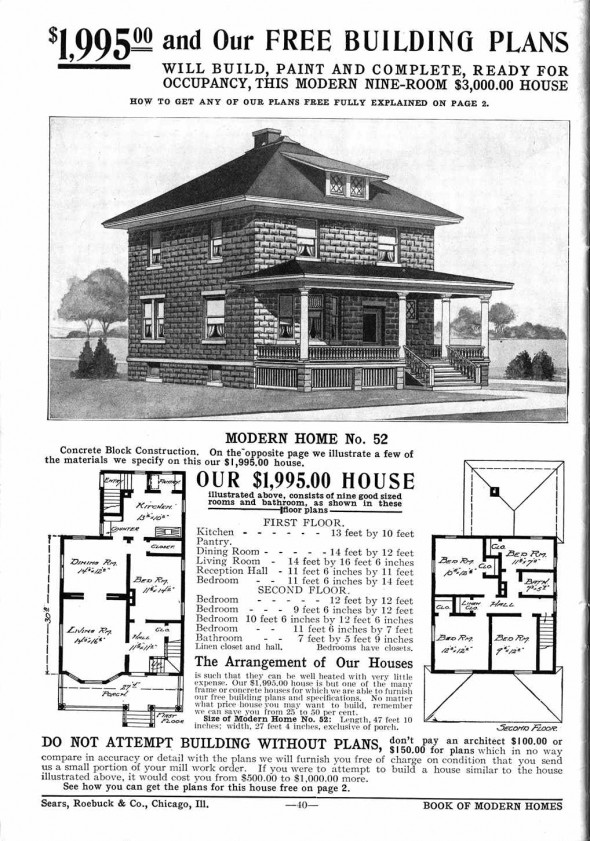

Chicago was selected as a key growth market, according to Guthrie, because of its proximity to the company’s production facility in Indiana, and because it provides a large market area with a history of progressive thinking in terms of architecture and building. Guthrie points out that early in the twentieth century, Chicago-founded Sears, Roebuck and Co. sold over 70,000 precut and prepackaged homes through their mail order Modern Homes program, which allowed customers to choose a house to suit their individual tastes and budgets. At approximately the same time, he goes on to explain, Frank Lloyd Wright introduced his textile block Usonian home concept to demonstrate that exceptional quality and design, using prefabricated components, can be made available to the masses.

“Conceptually, we stand on the shoulders of such Chicago icons as Sears and Frank Lloyd Wright, who paved the way for modular architecture,” Guthrie states. “Today, we are seeing a resurgence in modular architecture,” he continues. “The interest is driven in small part by economics, but more so by a desire for greener construction practices, creative design, and the caliber of high quality production that Miletus Group consistently delivers and will now extend into the Chicago market.”

Frank Lloyd Wright McBean House in Rochester, Minnesota. This Usonian house is an example of the second type (Prefab #2) of the Marshall Erdman Prefab Houses.

Sears Homes 1908 – 1914, Chicago, IL From the Sears Archives Model No. 52

Miletus Group’s Shotgun Project featured in Residential Architect Magazine

Miletus Group’s innovative Hurricane Katrina housing solution, named The Shotgun Project, was featured in the May/June issue of Residential Architect. According to Residential Architect, “Hurricane Katrina and the ensuing flooding left New Orleans with a significant housing crisis that has not yet been resolved. Rochester, Ind.–based design/build firm Miletus Group, which specializes in prefab and modular systems, has developed a prototype that may help.”

“These ingenious modular structures are substantial homes,” Miletus president James B. Guthrie, AIA notes, “fully compliant with current building codes and FEMA standards, offering a sustainable, permanent solution to the current and near-term housing needs of New Orleans.”

Click on the image below to read the entire article online.

Miletus Group’s green modular solutions featured in Building Indiana News

Miletus Group’s HPMO and Jobsite Leasing’s Green Fleet was featured in Building Indiana News in an article about new mobile and modular solutions. Click on the image below to read the article online – page 58. According to Building Indiana, “Miletus Group and Jobsite Leasing Company have created the mobile office industry’s first green options.” For more on the project, link to our previous blog story here.

No Less True: Mies vs Modular

View from Below the Eiffel Tower Paris, France

In the early days of iron and steel, these new building materials were seen as a practical solution to building issues, not aesthetic ones. Steel was something structural and capital engineers embraced early because it solved a building size and economic problem. Engineers like Gustav Eiffel learned early on how to exploit metal for long spans, primarily in bridges. When Eiffel turned a bridge 90 degrees and created the Eiffel Tower he opened a lot of eyes to the architectural expression steel can take. Yet, it took a couple more decades before Ludwig Mies van der Rohe came along and figured out how to make poetry and architecture out of steel.

Mies gave us great insight into his way of thinking when he said:

“This is no less true of steel and concrete than of wood, brick and stone. We must remember that everything depends on how we use a material, not on the material itself. New materials are not necessarily superior. Each material is only what we make it.”

Modular and off-site construction have been around for many decades now solving only practical problems. If Mies found himself in our time he might say:

Kluczynski Federal Building; Mies van der Rohe

“This is no less true of off-site construction than of on-site construction. We must remember that everything depends on how we use a method of construction, not on the method itself. New methods are not necessarily superior. Each method is only what we make it.”

It is time to thank the engineers for developing modular and off-site methods, but now it is also time for poetry and architecture in modular and off-site construction to emerge.

Architecture +

© Miletus Group, Inc. 2011

Is Modular Design Really Greener? Exploring Construction Waste Reduction.

© James B Guthrie, AIA 2011

Yes, there is no question that modular construction is greener. Take the example of construction waste – off-site methods are far more efficient in terms of construction waste reduction than on-site construction.

Here is one example; many on-site contractors will include up to a 10% material contingency in their projects to cover, among other things, damage from weather and trades damages during construction. Because on-site contractors do not normally store excess materials for future jobs, even if there were no damages, this 10% contingency winds up in the waste stream.

Off-site factories are naturally more efficient with their materials. At Miletus Group we own our own modular factory. When we calculate materials for a job we use a factor of 0% percent for weather and trades damages to materials. This makes our overall waste stream very small. Because our facility is organized and weather tight, it is very easy for us to handle materials and waste. Throughout our facility we have separate bins for various construction materials that we can not use again. This means recycling is easy for us and we wind up recycling over 95% of the limited waste we do generate. Very little of our construction material winds up in the landfill. It would be great if on-site builders could make similar claims, but it is highly improbable that on-site construction could ever meet these numbers due to the very nature of the environment in which they work.

Visit AIA’s new KnowledgeNet Modular and Prefabricated Architecture group. There are a couple of documents from the UK on this very subject. They are a few years ahead of us on this issue. It is good reading.

If anyone reading this has further data to support the efficiencies of off-site construction, please do feel free to let us know directly and we will post it.

© Miletus Group, Inc. 2011

Miletus NEWS: The Green Fleet marks industry’s first eco-friendly mobile field office fleet

Miletus Group, Inc. has joined forces with Jobsite Leasing Company to make mobile and modular offices eco-friendly. The Green Fleet™ marks a first in the industry, which has lagged behind conventional commercial building in terms of sustainable building practices. Mobile field offices, long a staple of the construction industry and present on virtually every construction site of medium and large construction projects around the world, are easily ignored as a ‘real’ building type.

When energy costs associated with the use and operation of Jobsite’s fleet of mobile and modular field offices started generating customer comment Jobsite decided to examine the possibilities of developing a green mobile building with the modular design experts at Miletus Group.

Miletus Group accepted the challenge. Miletus Group president and project spokesperson James B. Guthrie, AIA points out, “Our team spent a great deal of time analyzing the best sustainability practices in the building industry and then found ways to apply them to the mobile and modular office building sector.” Little will appear changed to office occupants in terms of the general layout, construction, and convenience of the high performance units, according to Guthrie. However, he states noticeable differences will appear in the form of substantially lower utility bills and significantly higher levels of comfort during hot summer and frigid winter months.

When asked why an architectural firm would be interested in a mobile office, Guthrie said: “If we were talking about one field office, one does have to wonder if the effort is worth creating 700 square feet of high performance building. However, our client is a fleet operator. They asked us to examine creating an entire fleet of these buildings. One’s perspective changes significantly when you add them all up.” According to the Modular Building Institute, there are approximately 300,000 fleet field offices in North America alone. That number represents over 200,000,000 square feet of green building potential. Guthrie added, “Doing this project felt a lot like planting the first tree in the creation of a forest. I might not get to sit in all that shade, but future generations sure will.”

Because this industry is highly cost driven, Jobsite first commissioned Miletus Group to perform a cost analysis to determine the feasibility of building high performance mobile and modular offices. Guthrie and his team began by doing alternative preliminary designs and then running a series of Department of Energy and USGCB LEED approved building performance computer models. The models provided a baseline analysis of the existing fleet against alternative design approaches. The results quickly proved that energy savings would offset initial green building costs. “The computer models were invaluable in assessing different approaches and creating a strategy for building procedures,” says Guthrie. With the help of the computer models, the manufacturer incorporated refinements in materials and production, which led to new efficient and cost-effective sustainable practices in the building of the High Performance Mobile Offices™, and a greater than 50 percent reduction in energy use. With the help of the Miletus design team, Jobsite was also able to dramatically reduce construction material waste, 95 percent of which is now recyclable. Additionally, the materials selection process was overhauled to include purchasing only from vendors that offer the largest inventory and highest degree of recyclable products on the market. The green building measures assured that the High Performance Mobile Offices would be 100 percent recyclable at the end of its life cycle. Moreover, Guthrie, who counts among his green building credentials, certified Green Advantage practitioner for commercial and residential construction, U.S. Green Building Council member, and member of the Modular Building Institute’s International Green Code review committee, expects ongoing field-monitoring reports will show building energy usage of sustainable-built High Performance Mobile Offices to be as little as one-third that of conventionally built, standard industry mobile offices.

On site at the USGBC LEED Platinum Transpo Center in South Bend, IN

HPMO, like a tree to a forest

HPMO with recommended insulated skirting

Full scale field office prototypes

© Miletus Group, Inc. 2011