Jobsite Mobile Office’s® Green Fleet® will be a featured attraction at the BCA Construction and Design Expo – Indiana’s largest construction trade show

The Green Fleet represents the world’s first eco-friendly HPMO (High Performance Mobile Office®) developed by the Miletus Group for Jobsite Mobile Offices. Jobsite Mobile Offices will feature the new Green Fleet HPMO at the BCA Construction and Design Expo – September 28-29, 2011 – Memorial Coliseum Exposition Center – Fort Wayne, Indiana. The 1260 HPMO will be located at the show entrance and will be fully furnished, manned, and powered.

Designed by the modular architecture specialists at Miletus Group, Inc., the HPMO installation is a pinnacle part of Jobsite Mobile Office’s 40th anniversary celebration taking place at the show.

About the Green Fleet HPMO Design

“We are proud of the work we did in partnership with Jobsite,” states James B. Guthrie, AIA, Miletus Group president. “The revolutionary HPMO uses at least one third less energy than conventional mobile offices. Some customers are reporting energy savings of well over 50%. This new thinking in mobile office design also includes a high level of recycled materials and is 100% recyclable at the end of its long life cycle. Our team spent a great deal of time analyzing the best sustainability practices in the building industry and then found ways to apply them to the mobile and modular office-building sector. Little will appear changed to office occupants in terms of the general layout, construction, and convenience of the high performance units. However, noticeable differences will appear in the form of substantially lower utility bills and significantly higher levels of comfort during hot summer and frigid winter months,” says Guthrie.

The Jobsite Green Team celebrates their 40th Anniversary at the BCA Construction and Design Expo. The Miletus Group designed the innovative HPMO to be featured at the Expo.

McGraw Hill: Prefabrication and Modularization

McGraw Hill Construction’s recent publication of “Prefabrication and Modularization: Increasing Productivity in the Construction Industry” provides a deep look into current thinking and trends surrounding off-site construction in the US. Overall, the report is very good and worth taking the time to read and ponder the implications of its contents.

While it is a bit disappointing that McGraw Hill did not tackle the important but less tangible aspects of architecture and design, the contents do provide the reader with a broad understanding of the benefits of this method of construction. Architects who read it won’t walk away with an immediate or complete tool set for how to design buildings for off-site construction, but, and this is also important, they will have a few more heavy duty tools for talking to their clients about it as an option for their upcoming architectural projects. According to the report, the number one reason that off-site is not used on more building projects is because “the architect did not design it into the project.”

Why should architects care? The report does a very good job of answering this question. According to McGraw Hill’s research, prefabrication and modularization offers the building process many improvements in a number of key fronts. These include:

- Improved Project Schedules

- Reduced Cost and Budgets

- Site Safety

- Green Building and Waste Reduction

The report goes into great detail about its findings in these areas. If you want some tools to learn about and be able to talk to the issues of increasing construction productivity, we invite you to read the report for yourself.

– – –

The Modular Building Institute Educational Foundation is offering a limited number of full color printed editions this report in exchange for a $100 or more tax-deductible donation to the Foundation. You can contact us through the comment area if you would like to make a donation and receive a copy/copies of the report.

© Miletus Group, Inc. 2011

McGraw Hill: Increasing Productivity in the Construction Industry

McGraw Hill Construction recently published a document called: “Prefabrication and Modularization: Increasing Productivity in the Construction Industry.”* This is the latest in their Smart Market Reports, a series they publish on construction industry trends.

McGraw Hill Construction recently published a document called: “Prefabrication and Modularization: Increasing Productivity in the Construction Industry.”* This is the latest in their Smart Market Reports, a series they publish on construction industry trends.

A lot of research went into the report and it contains many interesting sub-topics. However, it only takes a quick look at the cover to find the first item of note. The report’s sub-title is: “Increasing Productivity in the Construction Industry.”

Most people who work in the construction industry are keenly aware that traditional site-built methods of construction have a bad reputation when it comes to efficiency. Likewise, most building owners and developers are keenly aware that those efficiencies hit the pocket book hard as they manifest themselves as poor quality work, change orders and completion delays. That McGraw Hill chose to include off-site construction in the general discussion of how we build all buildings is a huge step in the right direction of understanding that there is a better option in the way we create and assemble buildings.

This is a significant notion. Most non-industry discussions about prefabrication tend to see it as an anomaly, a mere curiosity for small scale players. They relinquish ‘prefab’ to the sidelines of the greater discussion of how we build all buildings, big and small. Those of us who currently practice in the off-site industry understand how efficient this method of construction really is and generally have a large vision of how important a role it can play in curing the productivity woes found with on-site construction. That McGraw Hill decided to take this on with an in depth analysis is in itself worthy of mention.

* While primarily researched and published by McGraw Hill, this Smart Market report included a number of partners. One partner was the Modular Building Institute Educational Foundation, of which James B. Guthrie, AIA, President of Miletus Group, is the Chair.

– – –

The Modular Building Institute Educational Foundation is offering a limited number of full color printed editions this report in exchange for a $100 or more tax-deductible donation to the Foundation. You can contact us through the comment area if you would like to make a donation and receive a copy/copies of the report.

© Miletus Group, Inc. 2011

Miletus Group Develops an Architecturally Appealing Rescue Strategy for New Orleans’ Post-Katrina Housing Crisis

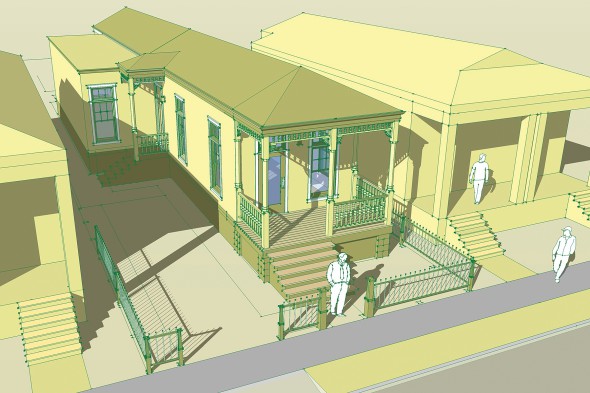

The modular design experts at architecture firm Miletus Group, Inc. have been selected by a prominent housing developer and landowner to develop their Shotgun House Project™—a historically and architecturally sensitive approach to quickly address New Orleans’ post-Katrina housing crisis. After extensive project prototype work, the first Shotgun House model has been designed for an Uptown lot and is slated for completion this year.

The modular design experts at architecture firm Miletus Group, Inc. have been selected by a prominent housing developer and landowner to develop their Shotgun House Project™—a historically and architecturally sensitive approach to quickly address New Orleans’ post-Katrina housing crisis. After extensive project prototype work, the first Shotgun House model has been designed for an Uptown lot and is slated for completion this year.

Miletus Group’s Shotgun Homes are architectural-quality, permanent modular buildings designed to fit into New Orleans’ neighborhoods as if they had been there for a century or more. These ingenious modular structures are substantial homes, fully compliant with current building codes and FEMA standards, offering a sustainable, permanent solution to the current and near-term housing needs of New Orleans.

“Hurricane Katrina’s lasting effects have created a massive housing deficit in New Orleans,” states Miletus Group president James B. Guthrie, AIA. “This housing dilemma is exacerbated by labor shortages and the high price of available building materials. Our premise was to build high quality, and architecturally sensitive homes off site, away from the stresses of New Orleans’ building environment. These modular buildings could then be put in place quickly, reducing time to occupancy, and alleviating much of the inconvenience and noise pollution in the neighborhoods where they are being constructed.” Miletus is renowned for their sustainable building expertise, particularly in modular structures.

“Hurricane Katrina’s lasting effects have created a massive housing deficit in New Orleans,” states Miletus Group president James B. Guthrie, AIA. “This housing dilemma is exacerbated by labor shortages and the high price of available building materials. Our premise was to build high quality, and architecturally sensitive homes off site, away from the stresses of New Orleans’ building environment. These modular buildings could then be put in place quickly, reducing time to occupancy, and alleviating much of the inconvenience and noise pollution in the neighborhoods where they are being constructed.” Miletus is renowned for their sustainable building expertise, particularly in modular structures.

The Shotgun Project offers a variety of home options, from fully completed and ready-for-occupancy, to fully customizable homes that are left partially unfinished as a more affordable choice for more handy do-it-yourselfers in need of immediate shelter. “The innovative Shotgun House design recalls the past, while providing comfortable, modern housing for its occupants,” states Guthrie. “It is a durable and permanent solution for a desirable housing type that is based on generations of New Orleans history and precedent.”

The Shotgun Project offers a variety of home options, from fully completed and ready-for-occupancy, to fully customizable homes that are left partially unfinished as a more affordable choice for more handy do-it-yourselfers in need of immediate shelter. “The innovative Shotgun House design recalls the past, while providing comfortable, modern housing for its occupants,” states Guthrie. “It is a durable and permanent solution for a desirable housing type that is based on generations of New Orleans history and precedent.”

For more information, contact Miletus Group, Inc.

© Miletus Group, Inc. 2011

Miletus NEWS: The Green Fleet marks industry’s first eco-friendly mobile field office fleet

Miletus Group, Inc. has joined forces with Jobsite Leasing Company to make mobile and modular offices eco-friendly. The Green Fleet™ marks a first in the industry, which has lagged behind conventional commercial building in terms of sustainable building practices. Mobile field offices, long a staple of the construction industry and present on virtually every construction site of medium and large construction projects around the world, are easily ignored as a ‘real’ building type.

When energy costs associated with the use and operation of Jobsite’s fleet of mobile and modular field offices started generating customer comment Jobsite decided to examine the possibilities of developing a green mobile building with the modular design experts at Miletus Group.

Miletus Group accepted the challenge. Miletus Group president and project spokesperson James B. Guthrie, AIA points out, “Our team spent a great deal of time analyzing the best sustainability practices in the building industry and then found ways to apply them to the mobile and modular office building sector.” Little will appear changed to office occupants in terms of the general layout, construction, and convenience of the high performance units, according to Guthrie. However, he states noticeable differences will appear in the form of substantially lower utility bills and significantly higher levels of comfort during hot summer and frigid winter months.

When asked why an architectural firm would be interested in a mobile office, Guthrie said: “If we were talking about one field office, one does have to wonder if the effort is worth creating 700 square feet of high performance building. However, our client is a fleet operator. They asked us to examine creating an entire fleet of these buildings. One’s perspective changes significantly when you add them all up.” According to the Modular Building Institute, there are approximately 300,000 fleet field offices in North America alone. That number represents over 200,000,000 square feet of green building potential. Guthrie added, “Doing this project felt a lot like planting the first tree in the creation of a forest. I might not get to sit in all that shade, but future generations sure will.”

Because this industry is highly cost driven, Jobsite first commissioned Miletus Group to perform a cost analysis to determine the feasibility of building high performance mobile and modular offices. Guthrie and his team began by doing alternative preliminary designs and then running a series of Department of Energy and USGCB LEED approved building performance computer models. The models provided a baseline analysis of the existing fleet against alternative design approaches. The results quickly proved that energy savings would offset initial green building costs. “The computer models were invaluable in assessing different approaches and creating a strategy for building procedures,” says Guthrie. With the help of the computer models, the manufacturer incorporated refinements in materials and production, which led to new efficient and cost-effective sustainable practices in the building of the High Performance Mobile Offices™, and a greater than 50 percent reduction in energy use. With the help of the Miletus design team, Jobsite was also able to dramatically reduce construction material waste, 95 percent of which is now recyclable. Additionally, the materials selection process was overhauled to include purchasing only from vendors that offer the largest inventory and highest degree of recyclable products on the market. The green building measures assured that the High Performance Mobile Offices would be 100 percent recyclable at the end of its life cycle. Moreover, Guthrie, who counts among his green building credentials, certified Green Advantage practitioner for commercial and residential construction, U.S. Green Building Council member, and member of the Modular Building Institute’s International Green Code review committee, expects ongoing field-monitoring reports will show building energy usage of sustainable-built High Performance Mobile Offices to be as little as one-third that of conventionally built, standard industry mobile offices.

On site at the USGBC LEED Platinum Transpo Center in South Bend, IN

HPMO, like a tree to a forest

HPMO with recommended insulated skirting

Full scale field office prototypes

© Miletus Group, Inc. 2011