Green Building – The Role of Creativity – Self Regulation vs. Universal Codes

Prefabrication and modern methods of construction (MMC) offer tremendous opportunity for creating better architecture and more sustainable environments.

Prefabrication and modern methods of construction (MMC) offer tremendous opportunity for creating better architecture and more sustainable environments.

Because MMC is a relatively new method of construction, many people in the building world still do not have a good understanding of what MMC is and what it brings to the table in the way of sustainable building opportunities. They are many, but a lack of knowledge could stifle this method as a solution to advancing green building.

LEED drives green creativity in U.S.

By now most people have heard about the U.S. Green Building Council (USGBC) and their LEED rating system. In just over ten years the USGBC went from non-existence to being “The” standard for green building in the U.S. The USGBC has done a lot of things right in their short life, but one reason their LEED ranking system is so popular is because it acknowledges, allows and even encourages creativity and flexibility, by the architects and the building team, to create a green building. The USGBC approach deserves a lot of credit for making green building something the marketplace is now demanding, and thus the market is now driving further aggressiveness and creativity in the building market here in the U.S.

Do government regulations stifle creativity?

Architects and builders in Europe are actually jealous of our success in this area. But why? When someone from the U.S. looks from afar at what some of the European countries are doing, we might see them as being more successful at green building than the U.S. What they have done (differently) is to mandate green building through government regulation. Some countries have gone so far as to mandate “zero carbon footprints” and “net zero energy” for buildings within 15 years. These are great concepts to be sure, but so far there is no agreement on what these terms actually mean and so they will be very difficult to regulate. Are they regulating creativity or stifling it?

As of yet, the U.S. has not taken the regulatory approach, yet the free market keeps pushing us in a greener and greener direction – again thanks to the USGBC model. However, some fear that the market may never fully embrace these ideas beyond certain niche buildings, or that the building market will at some point slow down and forget about sustainability, falling back to its old ways of being an energy hog.

Regulation can be good and bad. Generally, when a market is regulated, as in the implementation of building codes, it tends to get micro-managed by government, and creativity gets stifled.

Could IgCC wind up hurting creativity in U.S.?

Currently the International Code Council (ICC), a US based independent code authoring organization, is in the process of finalizing their first International Green Construction Code for the US. Like the European model, the IgCC is an attempt at creating a codified legal structure to mandate green building. This will absolutely create a massive process and bureaucracy to implement. It is very likely going to have the negative effect of stifling creative green building solutions.

If the IgCC follows the standard building code model, the building construction process will likely shift from trying to be as green as one can be, to being as code compliant as one needs to be to get a permit. If one has a new idea, yet it does not fit within the regulatory framework of the code, it becomes incredibly difficult to implement. Many hurdles will be thrown up by the code and permit process, such as: bureaucratic red tape, lawyers, excessive testing, layers and layers of review and finally delays waiting for inclusion in a future versions of the code to include new language.

The IgCC is not done being written yet, but it is getting very close.

Because the Miletus Group and others are pushing the envelope on new building methods, without some accommodation for creative innovation, such as consideration for the benefits of off-site construction, the IgCC could have a the opposite effect of its stated purpose. We would, therefore, advocate for an IgCC implementation process that not only allows for creative solutions but also, as in the USGBC model, encourages it!

© Miletus Group, Inc. 2011

No Less True: Mies vs Modular

View from Below the Eiffel Tower Paris, France

In the early days of iron and steel, these new building materials were seen as a practical solution to building issues, not aesthetic ones. Steel was something structural and capital engineers embraced early because it solved a building size and economic problem. Engineers like Gustav Eiffel learned early on how to exploit metal for long spans, primarily in bridges. When Eiffel turned a bridge 90 degrees and created the Eiffel Tower he opened a lot of eyes to the architectural expression steel can take. Yet, it took a couple more decades before Ludwig Mies van der Rohe came along and figured out how to make poetry and architecture out of steel.

Mies gave us great insight into his way of thinking when he said:

“This is no less true of steel and concrete than of wood, brick and stone. We must remember that everything depends on how we use a material, not on the material itself. New materials are not necessarily superior. Each material is only what we make it.”

Modular and off-site construction have been around for many decades now solving only practical problems. If Mies found himself in our time he might say:

Kluczynski Federal Building; Mies van der Rohe

“This is no less true of off-site construction than of on-site construction. We must remember that everything depends on how we use a method of construction, not on the method itself. New methods are not necessarily superior. Each method is only what we make it.”

It is time to thank the engineers for developing modular and off-site methods, but now it is also time for poetry and architecture in modular and off-site construction to emerge.

Architecture +

© Miletus Group, Inc. 2011

Is Modular Design Really Greener? Exploring Construction Waste Reduction.

© James B Guthrie, AIA 2011

Yes, there is no question that modular construction is greener. Take the example of construction waste – off-site methods are far more efficient in terms of construction waste reduction than on-site construction.

Here is one example; many on-site contractors will include up to a 10% material contingency in their projects to cover, among other things, damage from weather and trades damages during construction. Because on-site contractors do not normally store excess materials for future jobs, even if there were no damages, this 10% contingency winds up in the waste stream.

Off-site factories are naturally more efficient with their materials. At Miletus Group we own our own modular factory. When we calculate materials for a job we use a factor of 0% percent for weather and trades damages to materials. This makes our overall waste stream very small. Because our facility is organized and weather tight, it is very easy for us to handle materials and waste. Throughout our facility we have separate bins for various construction materials that we can not use again. This means recycling is easy for us and we wind up recycling over 95% of the limited waste we do generate. Very little of our construction material winds up in the landfill. It would be great if on-site builders could make similar claims, but it is highly improbable that on-site construction could ever meet these numbers due to the very nature of the environment in which they work.

Visit AIA’s new KnowledgeNet Modular and Prefabricated Architecture group. There are a couple of documents from the UK on this very subject. They are a few years ahead of us on this issue. It is good reading.

If anyone reading this has further data to support the efficiencies of off-site construction, please do feel free to let us know directly and we will post it.

© Miletus Group, Inc. 2011

Miletus Group Develops an Architecturally Appealing Rescue Strategy for New Orleans’ Post-Katrina Housing Crisis

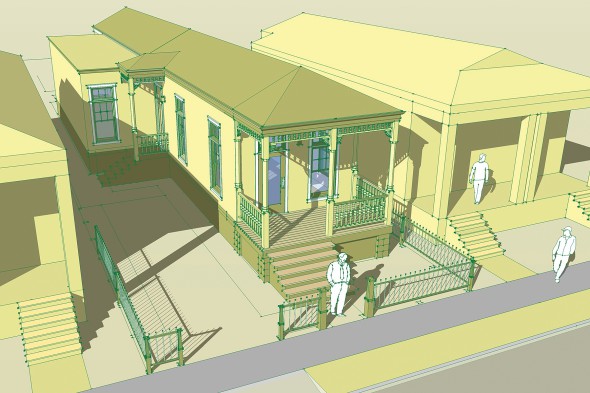

The modular design experts at architecture firm Miletus Group, Inc. have been selected by a prominent housing developer and landowner to develop their Shotgun House Project™—a historically and architecturally sensitive approach to quickly address New Orleans’ post-Katrina housing crisis. After extensive project prototype work, the first Shotgun House model has been designed for an Uptown lot and is slated for completion this year.

The modular design experts at architecture firm Miletus Group, Inc. have been selected by a prominent housing developer and landowner to develop their Shotgun House Project™—a historically and architecturally sensitive approach to quickly address New Orleans’ post-Katrina housing crisis. After extensive project prototype work, the first Shotgun House model has been designed for an Uptown lot and is slated for completion this year.

Miletus Group’s Shotgun Homes are architectural-quality, permanent modular buildings designed to fit into New Orleans’ neighborhoods as if they had been there for a century or more. These ingenious modular structures are substantial homes, fully compliant with current building codes and FEMA standards, offering a sustainable, permanent solution to the current and near-term housing needs of New Orleans.

“Hurricane Katrina’s lasting effects have created a massive housing deficit in New Orleans,” states Miletus Group president James B. Guthrie, AIA. “This housing dilemma is exacerbated by labor shortages and the high price of available building materials. Our premise was to build high quality, and architecturally sensitive homes off site, away from the stresses of New Orleans’ building environment. These modular buildings could then be put in place quickly, reducing time to occupancy, and alleviating much of the inconvenience and noise pollution in the neighborhoods where they are being constructed.” Miletus is renowned for their sustainable building expertise, particularly in modular structures.

“Hurricane Katrina’s lasting effects have created a massive housing deficit in New Orleans,” states Miletus Group president James B. Guthrie, AIA. “This housing dilemma is exacerbated by labor shortages and the high price of available building materials. Our premise was to build high quality, and architecturally sensitive homes off site, away from the stresses of New Orleans’ building environment. These modular buildings could then be put in place quickly, reducing time to occupancy, and alleviating much of the inconvenience and noise pollution in the neighborhoods where they are being constructed.” Miletus is renowned for their sustainable building expertise, particularly in modular structures.

The Shotgun Project offers a variety of home options, from fully completed and ready-for-occupancy, to fully customizable homes that are left partially unfinished as a more affordable choice for more handy do-it-yourselfers in need of immediate shelter. “The innovative Shotgun House design recalls the past, while providing comfortable, modern housing for its occupants,” states Guthrie. “It is a durable and permanent solution for a desirable housing type that is based on generations of New Orleans history and precedent.”

The Shotgun Project offers a variety of home options, from fully completed and ready-for-occupancy, to fully customizable homes that are left partially unfinished as a more affordable choice for more handy do-it-yourselfers in need of immediate shelter. “The innovative Shotgun House design recalls the past, while providing comfortable, modern housing for its occupants,” states Guthrie. “It is a durable and permanent solution for a desirable housing type that is based on generations of New Orleans history and precedent.”

For more information, contact Miletus Group, Inc.

© Miletus Group, Inc. 2011

Pushing the limits of modular design.

© James B. Guthrie, AIA 2011

At 25 stories, Victoria Hall, in Wolverhampton, England, is the world’s tallest building built with off-site construction methods.

Built as an apartment complex for students at the University of Wolverhampton, Victoria Hall consists of four buildings, and is a substantial architectural solution to urban housing and tight building sites in this historic English town, about 110 miles northwest of London. The tallest building of the group is of particular note because, at 25 stories, it now holds the record for overall height and number of stories in a building constructed principally off-site. The ground floor is site-built, but the other 24 stories are assembled from 383 individual modules built several hundred miles away across land and sea in Cork, Ireland.

Challenged with the multiple pressures of speed, quality, and scale, the project team investigated alternative methods of project delivery. Vision Modular Structures, a division of The Fleming Group, entered the picture. The Fleming Group is a general contractor, Vision is their modular building division. Fleming/Vision, which has completed several other modular projects in their native Ireland, was contracted to build both the modules and the site-built components. Fleming also provided general construction management.

Considering that the demands of this project in general were substantial and that this project is the first time many on the project team had worked with modular methods, it is interesting to know that when asked if they would do it again, the common response is “absolutely.”

“In spite of this being a new method for most team members, the project went smoothly, quickly, stayed on budget, maintained our quality objectives and architectural integrity, and will actually be done ahead of our originally aggressive schedule, ” says Jenny Hayes, RIBA, O’Connell East’s project architect on Victoria Hall.

It is hard to argue with that.

For the full article, click here.

© Miletus Group, Inc. 2011