India: Demand for Housing Stresses Nation

BuildOffsite Delegation Answers the Call

B uildOffsite (www.buildoffsite.com), the leading global organization of allied professionals for modern methods of construction, was recently asked to visit India on a knowledge sharing expedition. The reason for the trip was to meet with academic, industry and government leaders to assist in finding solutions to the challenge of housing the world’s second largest and fast growing population.

uildOffsite (www.buildoffsite.com), the leading global organization of allied professionals for modern methods of construction, was recently asked to visit India on a knowledge sharing expedition. The reason for the trip was to meet with academic, industry and government leaders to assist in finding solutions to the challenge of housing the world’s second largest and fast growing population.

James B. Guthrie, AIA, President of Miletus Group, Inc. was asked to join the small and prestigious problem solving delegation which also included allied professionals from India, New Zealand and Great Britain.

Pressure is Building

India is challenged by both the current size of its population, now over 1.2 billon, and its substantial projected population growth. 65% of India’s population is under 35 years old. While China is currently the largest country in terms of population, India is a close second and growing at a faster pace than China. Projections indicate that India’s population will surpass China by 2030. In addition to the overall growth of the population, the country is also rapidly changing from rural to urban based. While India is already the densest country in the world, currently only 31% of the population live in urban areas. As this shift continues there will be greater and greater pressure on building and supporting infrastructure in urban areas. Massive amounts of green field sites are being consumed to accommodate expanding urban lands.

India is challenged by both the current size of its population, now over 1.2 billon, and its substantial projected population growth. 65% of India’s population is under 35 years old. While China is currently the largest country in terms of population, India is a close second and growing at a faster pace than China. Projections indicate that India’s population will surpass China by 2030. In addition to the overall growth of the population, the country is also rapidly changing from rural to urban based. While India is already the densest country in the world, currently only 31% of the population live in urban areas. As this shift continues there will be greater and greater pressure on building and supporting infrastructure in urban areas. Massive amounts of green field sites are being consumed to accommodate expanding urban lands.

Current estimates indicate that India has an existing housing shortage of over 18 million dwelling units at every income level. With the upcoming population growth and urban migration, this number is expected to become even more staggering over the coming years. India is in the midst of a very real housing and building crisis of unimaginable proportions and stands in a unique place in the world.

Population and Growth Rates 2012 – Three Largest Countries

| Country | Population | Growth Rate | Annual Growth |

| USA | 313,847,465 | 0.9% | 2,900,000 |

| India | 1,205,073,612 | 1.3% | 15,700,000 |

| China | 1,343,239,923 | 0.5% | 6,700,000 |

What this all means is that India needs a lot of new buildings and they need them quickly. Along with homes, other buildings like schools, hospitals, police stations, and stores are also needed to support the growing population. This huge demand has been creating substantial pressure on the existing construction supply chain, which still uses fairly traditional building methods. As a result, there is simply not enough skilled labor or production facilities to keep up with the demand.

BuildOffsite Called to Help

Fortunately, India’s leaders understand the dilemma and are seeking solutions to it. Thanks to forward thinkers and organizations like BuildOffsite, word has been spreading around the world that offsite methods of construction can deliver buildings more efficiently and of greater quality than traditional building methods. India sees prefabrication as a major way forward in their construction industry. Miletus Group was there to join in the solution based conversations and to promote the idea of not just fast building, but quality building including achieving social, architectural and sustainability goals.

While rapid population growth can tend to focus discussions on expediency, cost and logistics, this can spell social disaster if cultural history and social norms are forgotten in the process. India, especially, has a long and impressive cultural tradition of building magnificent buildings, most notably displayed in the elegant Taj Mahal. Over 350 years old, the Taj Mahal is as beautiful now as the day it was completed. This is due to the obsession with quality that its builders had, and is a good lesson that should not be forgotten in today’s climate of need. Architecture feeds the soul of a nation and provides future inspiration through generations of thoughtful predecessors. Factory made ‘ticky-tacky little boxes’ may provide a temporary fix, but good design, no matter how humble, will add permanency and pride to an enduring built environment. Architects must be a part of the solution and the transformation from traditional to modern methods of construction.

While rapid population growth can tend to focus discussions on expediency, cost and logistics, this can spell social disaster if cultural history and social norms are forgotten in the process. India, especially, has a long and impressive cultural tradition of building magnificent buildings, most notably displayed in the elegant Taj Mahal. Over 350 years old, the Taj Mahal is as beautiful now as the day it was completed. This is due to the obsession with quality that its builders had, and is a good lesson that should not be forgotten in today’s climate of need. Architecture feeds the soul of a nation and provides future inspiration through generations of thoughtful predecessors. Factory made ‘ticky-tacky little boxes’ may provide a temporary fix, but good design, no matter how humble, will add permanency and pride to an enduring built environment. Architects must be a part of the solution and the transformation from traditional to modern methods of construction.

The Future is Now

India is a place of action. Changes to the building industry are occurring right now. Prefabricated techniques are being used in the way of precast concrete buildings. The systems are however, still a bit rough and rely on traditional onsite skills used in an offsite location. Coming soon, though are more modern offsite factories and methods that use lighter and faster framing and more sustainable building practices.

India is a place of action. Changes to the building industry are occurring right now. Prefabricated techniques are being used in the way of precast concrete buildings. The systems are however, still a bit rough and rely on traditional onsite skills used in an offsite location. Coming soon, though are more modern offsite factories and methods that use lighter and faster framing and more sustainable building practices.

The positive energy expressed by the Indian hosts of the BuildOffsite delegation was palatable. They are ready to implement big ideas at big scales. It is not too big a stretch to imagine India, in just a few years, as the world leader in offsite construction. Miletus Group is proud and excited to have been a part of these early talks. We also look forward to being a part of the growth that is India’s present and future life.

* Demographic information from various governmental websites.

Zero Net Energy Classroom at Modular Architecture Group

Zero Net Energy Classroom at Modular Architecture Brown Bag Group meeting Jan 31, 2012 in San Diego

The discussion will include American Modular Systems’ CHPS verified and award winning zero net energy Gen7 modular classroom.

January’s guest will be Jim Wallace of AMS. AMS is a California manufacturer of commercial, institutional, and modular buildings.

All AIA members are welcome to join the meeting.

Brown Bag Roundtable: Modular Architecture

Tuesday, January 31, 2012 — 12:00 – 1:30PM

AIA San Diego Chapter Office

© Miletus Group, Inc. 2012

Modular Architecture Q&A: New Materials or Technologies

Below is the next post, number 5, in the continuing series of prefab/modular Q&A asked by Norman Gray, a graduate student at the New School of Architecture and Design in San Diego, CA and answered by James B. Guthrie, AIA, President of Miletus Group, Inc.

Question:

Are there any new materials or technologies which are making prefab construction more cost effective?

Answer:

As far as I am aware, no none that directly pertain to offsite construction.

There are some new building materials on the horizon that show promise, but as of yet they have not made it into prefab production. At this time, the cost benefit of prefab is in the process, not the materials. This could easily change in the near future as the supply chain becomes more robust, but for now the focus has been on tweaking standard methods to make building more cost effective.

Manufacturing processes that allow repetitive work to be done quickly is the chief driver of prefab right now. Quick assembly once on the site is another. Use of sustainable building practices is yet another. Perhaps one aspect of using manufactured processes that is a new benefit to the building world is the idea of greater precision in building. Products produced in a factory setting are inherently built more accurately than on site work. This can translate into stronger and more efficient buildings. The application of the methodology to architecture is somewhat new. The building materials and technologies, however, still tend to parallel standard construction.

Related link: http://www.newschoolarch.edu

© Miletus Group, Inc. 2012

Modular Architecture Q&A: Transportation Costs

Below is the second post in the continuing series of prefab/modular Q&A asked by Norman Gray, a graduate student at the New School of Architecture and Design in San Diego, CA and answered by James B. Guthrie, AIA, President of Miletus Group, Inc.

Question:

Is transportation of prefab/modular units a significant cost factor?

Answer:

The general answer would be ‘yes’, but how significant is dependent on the details of the project. These details include: the distance and travel conditions between the project and the factory, the size and weight of the prefab components, and the cost of labor at the two locations. To illustrate the extremes, I am aware of projects that were as simple as lightweight bathrooms pods built less than a mile from the project site, to very heavy fully furnished apartment modules that were shipped hundreds of miles, over both seas and roads, and even between two countries. The cost of the transportation was clearly very different being much greater in the second example, yet both projects made financial sense.

To understand the impacts of transportation, keep in mind that costs associated with transportation are not new or exclusive to prefab vs site built. All building construction has transportation costs inherent in the project. Regardless of the method of construction, both materials and labor come from somewhere other than the construction site.

To understand the differences, however, let’s first consider the case of the transportation of labor. In this regard, offsite construction is particularly efficient vs onsite. Workers at a factory tend to live near the factory and so have very consistent and minimal travel distances to the work site (ie the factory). Additionally, carpooling and other energy efficient commuting options become very real in this scheme. In the case of onsite construction, the travel distance for labor is a variable and completely dependent on the location of the trades needed and the building being constructed. Onsite construction requires a more skilled labor force than offsite construction. It is often the case the specialty trades will travel greater distances to reach a construction site than unskilled labor to factories. For onsite construction the location of the worker to the work site is in constant flux with each building built. This is not so with offsite methods.

There is a similar effect with the delivery of materials. Offsite construction occurs on singular factory sites where there tends to be large and protected staging areas. This means materials can be ordered and stored in weather protected areas in bulk far in advance of assembly. Factories also tend to be geographically clustered and located within proximities to construction material suppliers. These two factors greatly increase the efficiency of material delivery to the point of assembly.

For prefab, there is then unique cost of transporting large assemblies to the building site. Unlike traditional onsite labor and material logistics, however, prefab assemblies carry with them substantial embodied bulk material and embodied bulk labor, and are thus extremely efficient transportation hauls.

Because of these efficiencies and the addition of labor to the total transportation cost of building, the equation of transportation related costs and its percentage of the total building cost, has many components and modifiers to consider in the final equation. This is why, depending on the project, it can actually be cost effective to ship large and heavy modules long distances.

Related link: http://www.newschoolarch.edu

© Miletus Group, Inc. 2011

Miletus Group Returns to its Roots! Opens Chicago Architectural Office

Miletus Group has officially announced the opening of its new office in Chicago, IL at 2823 N. Milwaukee Avenue, Suite E, (312) 265-6447. The new Chicago metropolitan location will house architectural services, building on the continued success of the Miletus Group management, design, and production operations in its Rochester, IN headquarters.

“The new design office gives us a great new platform to reach out to the entire Chicago metropolitan market,” says James B. Guthrie, AIA, president of Miletus Group, adding, “We have exciting plans for innovative, large-scale modular solutions involving hotel, apartment, and healthcare facility projects,” he further explains. “Chicago is a natural market for substantial building in these sectors, making it a perfect fit for our future growth strategy. In addition, Chicago is my hometown, so I very much look forward to working there with our staff of talented architects.”

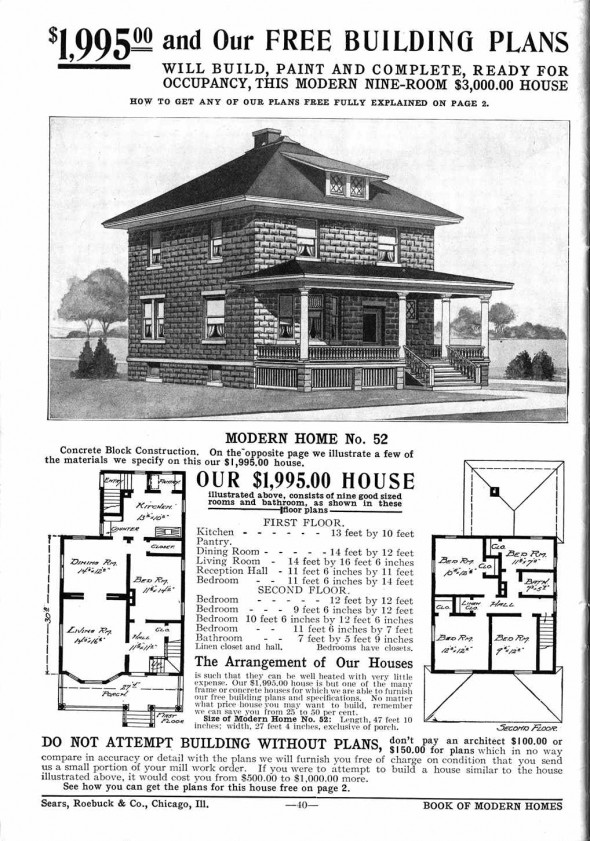

Chicago was selected as a key growth market, according to Guthrie, because of its proximity to the company’s production facility in Indiana, and because it provides a large market area with a history of progressive thinking in terms of architecture and building. Guthrie points out that early in the twentieth century, Chicago-founded Sears, Roebuck and Co. sold over 70,000 precut and prepackaged homes through their mail order Modern Homes program, which allowed customers to choose a house to suit their individual tastes and budgets. At approximately the same time, he goes on to explain, Frank Lloyd Wright introduced his textile block Usonian home concept to demonstrate that exceptional quality and design, using prefabricated components, can be made available to the masses.

“Conceptually, we stand on the shoulders of such Chicago icons as Sears and Frank Lloyd Wright, who paved the way for modular architecture,” Guthrie states. “Today, we are seeing a resurgence in modular architecture,” he continues. “The interest is driven in small part by economics, but more so by a desire for greener construction practices, creative design, and the caliber of high quality production that Miletus Group consistently delivers and will now extend into the Chicago market.”

Frank Lloyd Wright McBean House in Rochester, Minnesota. This Usonian house is an example of the second type (Prefab #2) of the Marshall Erdman Prefab Houses.

Sears Homes 1908 – 1914, Chicago, IL From the Sears Archives Model No. 52